INDUSTRIAL PAINTING, CALCULATE PAINT CONSUMPTION

What is volume solids in painting-

All paints are made up of resign, pigments solvents and adhesive ( like stabilizers, anti-foams, and thickeners). After the paint is applied solvent evaporates and leaving only the dry SOLIDS in the form of a continuous coating. the solid can be expressed as a volume percentage of the entire volume of the can of paint.

example- if a solvent is half of the paint volume then we can say that the paint is 50% solid.

means if the wet film thickness is 100 microns means after drying we shall get 50 microns in thickness.

%Volume Solid = Dry Film Thickness x 100 / Wet Film Thicknessif we take above example of 50%volume solids

%Volume Solid = 50 x100 / 100 = 50%

Relationship between spreading rate and VS (volume solids)

To achieve a given dry film thickness we can use the following formula to calculate wet film thickness

Wet Film Thickness = Dry Film Thickness x 100 / % Volume Solids

Spreading Rate (m2 / liter) = % Volume Solid x 10 / DFT Required

For Example-

If we need to paint an item where DFT required is 60 microns and paint which we have to use is having Volume Solids = 80%. Then with what DFT we have to paint the item so that after drying DFT should come equal to 60 microns?

Answer-

WFT = 60 microns x 100 / 80 = 75

to achieve this wet film thickness, what should be the spreading rate ( in square meters per liter )

spreading rate (m2/ltr) = % volume solids x 10 / DFT required

= 80 x 10 / 60 = 13.33 m2/liter

Addition of thinner affects Volume Solids & Wet Film Thickness

For ease of application, we often thin a product down in some condition. In this condition, the calculation will be different-

Corrected % Volume Solids = % Volume Solids x 100 / (100 + % Thinner added)

Corrected Wet Film Thickness = Dry film thickness x (100 + % Thinner added) / % Volume Solids

Example-

volume solids= 80%

DFT required= 60microns

thinner added= 5%

corrected % volume solids = % Volume Solids x 100 / (100 + % Thinner added)

= 80 x 100 / 100 +5

= 76.1%

Wet Film Thickness = Dry film thickness x 100 / corrected % Volume Solids

= 60 x 100 / 76.1

= 78.8 microns

spreading rate (m2/ltr) = corrected % volume solids x 10 / DFT required

= 76.1 x 10 / 60

= 12.68 m2/liter

The practical spreading rate depends on the following factors-

1) Type of object being painted ( shape)

2) pitting and rough surface need more paint to fill the surface

3) Wastage in a hose, brush, rollers, pots overspray, wind losses, etc.

4) Skill and experience of spray painting and painters.

5) Porosity of surfaces.

Paint loss-

1) by brush, roller & airless spray = 10 %

2) by conventional spray = 30 to 40%

PAINTING AREA

PAINT MIXING MACHINE

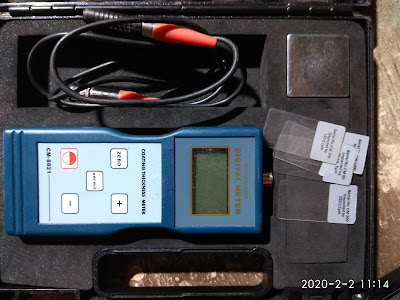

DFT GAUGE

WET FILM THICKNESS GAUGE

No comments:

Post a Comment

Please do not enter any spam link in the comment box