IMPACT TESTING OF MATERIAL

The impact test is used to study the toughness of any material. Toughness is a factor of its ability to absorb energy during its plastic deformation. Brittle material gives low impact value in comparison to ductile material.

MATERIAL TESTING- (IMPACT TESTING)

The impact test is used to study the toughness of any material. Toughness is a factor of its ability to absorb energy during its plastic deformation.

BRITTLE MATERIAL- LOW IMPACT VALUE

DUCTILE MATERIAL- HIGH IMPACT VALUE

Impact value decreases with a decrease in temperature

a typical machine used in impact testing-

V NOTCH CUTTING MACHINE

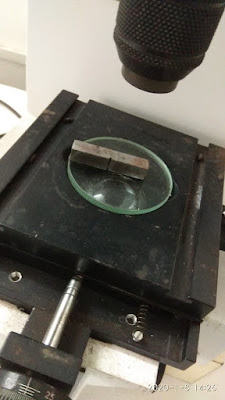

V NOTCH CHECKING MACHINE

The profile projector is used to measure the size of the v notch. VIDIO

WHY TITANIC FAILED

High Brittelness of steel was one of the reasons for the failure of Great Titanic, Date April 10' 1912 when TITANIC struck an iceberg and due to high brittle steel (10 times more brittle than modern steel) and very low temperature of the water, the steel used in the building was failed.

No comments:

Post a Comment

Please do not enter any spam link in the comment box