Saturday, February 29, 2020

Wednesday, February 26, 2020

PWHT, Stress reliving Procedure

PWHT / Stress reliving Procedure

1.0 Scope:-

This

describes the Procedures Provide information for heat treatment (Stress

relieving only) for Carbon steel, alloy steel.

2.0 Reference Codes & Specification:-

• ASME

Section VIII Div.1

• AWS

D1.1

• Railway

Specification.

•

Manufacturing Drawing.

•

Welder Procedure specification.

Labels:

welding

Tuesday, February 25, 2020

Procedure for Straightening by Heat Correction method for Structure

Procedure for Straightening by Heat Correction

Thermal techniques

"The basic principle behind the thermal process is to create high local stress so that, on cooling, the job is pulled back into shape. Local heating is a simple and effective process of correcting distortion. This process requires a lot of experience as there is no standard rule of shrinkage so any new job if repair is required then first it should be tested to establish correct shrinkage"

Buy Car & Vehicle Electronics Online

Buy Car & Vehicle Electronics Online at Amazon.in click the above link to buy...

कदम पर कुरकुरा, शक्तिशाली ध्वनि की मांग? निर्देशों के साथ मदद के लिए कार वीडियो या जीपीएस नेविगेशन सिस्टम खोज रहे हैं? अमेज़ॅन इंडिया आपको कार और वाहन इलेक्ट्रॉनिक्स की एक श्रृंखला के लिए ऑनलाइन खरीदारी करते समय एक शानदार अनुभव प्रदान करने के लिए समर्पित है। आप कार स्टीरियो, स्पीकर, लाइट, वायरलेस किट, चार्जर, जीपीएस सिस्टम, वैक्यूम क्लीनर और सुरक्षित और कई ऑनलाइन भुगतान विकल्पों के साथ सस्ती कीमतों पर खरीद सकते हैं। मनोरंजन और सुविधा संपन्न सिस्टम खोजने के लिए वाहन इलेक्ट्रॉनिक्स की लोकप्रिय श्रेणियों और सबसे ज्यादा बिकने वाली कार स्टीरियो के माध्यम से ब्राउज़ करें। दैनिक आवागमन या लंबी यात्राएं, जब आप एक ऐसी कार चलाना शुरू करते हैं, जो सभी इलेक्ट्रॉनिक प्रणालियों से सुसज्जित होती है, तो वे सभी अधिक सुखद होती हैं।

Monday, February 24, 2020

Sunday, February 23, 2020

CERAMIC BACKING STRIPS

CERAMIC BACKING STRIPS

ACHIEVEs

• X-Ray quality root welds In one

• Fu.ll penetration welds from one

• Uniform back beads of finished quality

• Root weld end fill in one pass

Application of Ceramic Backing Strip

3metres/minute and produce excellent and accurate bevels. The plates can be beveled, over a range of

6mm to 58mm; and the maximum bevel that can be cut is 28mm. A range of bevellers are available for bevelling different sections of Carbon Steel, Aluminum, Stainless Steel, and Titanium.

Saturday, February 22, 2020

WELD AND MAGNETIC FIELD

Effect of Magnetic Field on Welding...

EFFECT ON WELD GEOMETRY

A magnetic field can deflect the arc perpendicular to the welding direction as AC current changes its direction because the direction of electrons changes and this changes the direction of the force on them. This way arc is deflected from the line of a weld. This results in an increase in bead width also.

Friday, February 21, 2020

How to fix a logo in word

How to fix a logo in word

If you insert a logo by a conventional method, as shown in below picture then anyone can edit it in your office who don't know about developer tab (VBA)

To fix the logo, you need to activate the developer tab in your word or excel

Monday, February 17, 2020

shrinkage a big factor in welding

How to calculate shrinkage in welding

What is shrinkage?

In a welded joint, expansion and contraction forces act on the weld metal and on the base metal. As the weld metal solidifies and fuses with the base metal, in this stage, it is in its maximum expanded form. While cooling, weld metal contract to the volume it would normally occupy at the room temperature, but it is restricted by the adjacent base metal. Because of this, stresses develop within the weld metal and the adjacent base metal.

Labels:

welding

Saturday, February 15, 2020

HEAT INPUT IN ARC WELDING

ARC ENERGY AND HEAT INPUT IN ARC WELDING

In arc welding process, heat input HI and arc energy AE are measures of how much heat input has been supplied to the job being welded. unit of HI is kj/mm or kj/in. If travel speed is in mm then unit will be kj/mm

arc energy AE = 60VI / 1000s

I = CURRENT IN AMPS

V = VOLTAGE

s = TRAVEL SPEED OF WELDING

Thursday, February 13, 2020

Wednesday, February 12, 2020

INDUSTRIAL PAINTING, CALCULATE PAINT CONSUMPTION

INDUSTRIAL PAINTING, CALCULATE PAINT CONSUMPTION

What is volume solids in painting-

All paints are made up of resign, pigments solvents and adhesive ( like stabilizers, anti-foams, and thickeners). After the paint is applied solvent evaporates and leaving only the dry SOLIDS in the form of a continuous coating. the solid can be expressed as a volume percentage of the entire volume of the can of paint.

example- if a solvent is half of the paint volume then we can say that the paint is 50% solid.

means if the wet film thickness is 100 microns means after drying we shall get 50 microns in thickness.

Sunday, February 9, 2020

RAMS and LCC in rail product

RAMS and LCC in rail product manufacturing

All give great importance to this aspect throughout the project in the rail industry, like vehicles and their components. A customer requires reliable products that are easily maintainable throughout its lifetime. The cost of the product in the rail sector is affected by initial cost and also by operating and maintenance costs during its lifetime. All costs are added in the life of LCC from concept to last use of a product.

Labels:

ISO

TERMS USED IN ISO 22163

Abbreviations of terms used in ISO:22163-2017

Abbreviations

EPPPS Externally Provided Process, Product and services

FAI First Article Inspection

FMEA Failure Mode, Effects and Criticality Analysis

FMECA Failure Reporting Analysis and Corrective Action

System

KPI Key Performance Indicator

LCC Life Cycle Costing

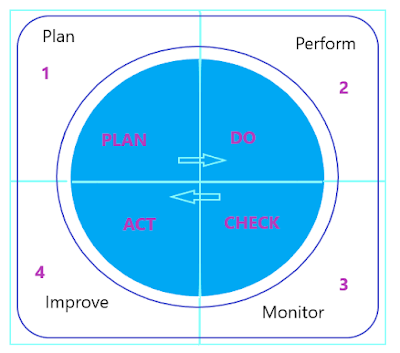

PDCA Plan – Do – Check – Act

QDC Quality Deficiency Cost

RAM Reliability, Availability, Maintainability

RAMS Reliability, Availability, Maintainability, Safety

RQMS Rail Quality Management System

SIL Safety Integrity Level

“Shall” indicates a requirement;

“Should” indicates a recommendation;

“May” indicates permission;

First Article Inspection

PURPOSE OF FAI

Purpose of FAI (first article inspection ) is to give objective & a documented record that all design, specification & requirements are correctly understood, verified, and recorded, also to validate the processes (including manufacturing gauges, jigs, and fixtures) of a new Product & major upgrade of any existing can be considered as a final requirement to release the mass production.

Saturday, February 8, 2020

8D MANAGEMENT TOOL

WHAT IS 8D ( MANAGEMENT TOOL )

THE EIGHT DISCIPLINES (8D)

8 steps to solve any problem in an organization-1: Create a group of people who know the activities and the company.

2: Define the problem.

3: Implement provisionally.

4: Identify the cause. of the incidence.

5: Determine permanent corrective actions (PCAs).

6: Implement permanent corrective actions.

7: Prevent similar problems.

8: Recognize the team’s work. (rewards)

Result: The use of the 8D method allows to improve a product, services, and processes.

---------------------------------

8D क्या होता है?

किसी संगठन में किसी भी समस्या को हल करने के लिए 8 कदम-

1: गतिविधियों और कंपनी को जानने वाले लोगों का एक समूह बनाएँ।

2: समस्या को परिभाषित करें।

3: अनंतिम रूप से लागू करें।

4: कारण की पहचान करें। घटना का।

5: स्थायी सुधारात्मक कार्यों (पीसीए) का निर्धारण करें।

6: स्थायी सुधारात्मक कार्यों को लागू करें।

7: इसी तरह की समस्याओं को रोकें।

8: टीम के काम को पहचानो। (पुरस्कार)

परिणाम: 8D विधि का उपयोग किसी उत्पाद, सेवाओं और प्रक्रियाओं को बेहतर बनाने में मदद देता है।

Labels:

ISO

Key performance indicators

What makes a KPI effective?

KPI MUST BE SMART

What makes a KPI effective?

KPI stands for key performance indicator it is valuable as the action it inspires.

for preparing a KPI, a team should start with the basics and understand the organizational objectives,

make a plan to achieve them, and decide who will act on this information. Interact with department heads and take feedback.

Friday, February 7, 2020

HOLI 2021 HOLI KE RANG

HOLI 2021, होली के रंग

HOLI 2021, होली के रंग

फागुन लाया होली संग

फैल गया सबमें उमंग

फूलों के खिलनें से

महक उठा सारा उपवन

रंग बिरंगी तितलियों से

सज गया सारा गुलशन

फूलों से पीकर भंग

गुनगुनाएं भवरे भी संग

हरे पीले नील रंगों से

हुआ आसमाँ का भी इन्द्र धनुषी रंग

आओ बच्चों मिलजुल हम

ऐसी मचाएं होली की हुड़दंग

बन जाएँ सब दोस्त हमारे

रहें न कोई भी दुश्मन

ऐसी कोई छेड़ें सरगम

Image by Prawny from Pixabay Thursday, February 6, 2020

Subscribe to:

Posts (Atom)